The spider crane, a marvel of modern engineering, is a small yet powerful machine designed for operations in confined spaces. Featuring manual or remote control capabilities, these cranes run on rubber tracks and boast a telescopic box boom. Predominantly manufactured in Japan, various companies contribute to the production of spider cranes, resulting in a range of prices and characteristics based on the manufacturer. Despite its compact design, the spider crane retains substantial lifting capacity, making it indispensable in urban construction and other industries. For those in need of reliable lifting equipment, Safest Lift offers a wide selection of spider cranes tailored to meet diverse project requirements.

Design and Construction

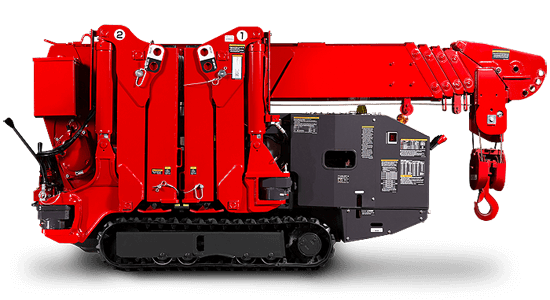

The spider crane’s design is reminiscent of a car, with a welded steel frame that ensures durability and strength. The compact dimensions of the device enhance its maneuverability, allowing it to operate efficiently in restricted areas. To bolster reliability, manufacturers reinforce components that bear the maximum load during operation with additional steel sheets. The crane is typically mounted on a wheeled or tracked chassis, optimizing stability and performance in various environments.

The frame’s narrow width is crucial for navigating tight spaces, while the reinforced steel structure ensures the crane can handle heavy loads without compromising safety. The use of rubber tracks instead of traditional wheels provides better traction and stability on uneven surfaces, making spider cranes versatile for both indoor and outdoor applications.

Historical Development

The origins of the spider crane date back to the 1960s in Japan, where the densely populated urban landscape necessitated innovative solutions for construction and industrial work. The first spider crane was introduced by Maeda in 1980, and by 1998, it had made its way into international markets. These mini-cranes addressed the challenges posed by limited space, allowing for efficient loading, unloading, and construction activities where full-size cranes were impractical.

The development of spider cranes was driven by the need to perform heavy lifting tasks in areas where traditional cranes could not fit. The ingenuity of Japanese engineers in the face of spatial constraints led to the creation of a machine that could be easily transported, set up, and operated in confined spaces. The success of Maeda’s initial model spurred other manufacturers to develop their own versions, further advancing the technology and expanding its capabilities.

Applications and Advantages

Spider cranes are versatile machines suitable for a wide range of applications, particularly in urban settings where space is at a premium. Their compact design allows them to be used in locations inaccessible to larger machines, such as shopping centers, airports, and private buildings. Spider cranes powered by gas are favored in eco-friendly projects like Masdar City in the UAE, where environmental considerations are paramount.

Case Studies

1. British Helicopter Museum, UK: In 2010, the museum faced a restoration challenge that required indoor work, eliminating the use of diesel or gasoline engines. A gas-powered spider crane with a width of 1.28 meters, a lifting capacity of 2.98 tons, and a lifting height of 12.52 meters was employed, successfully restoring two valuable exhibits without compromising the indoor environment. The crane’s ability to operate indoors without emitting harmful fumes made it an ideal choice for the museum’s delicate restoration work.

2. Park Hotel Vitznau, Switzerland: During a 2009 renovation, the hotel needed to restore antique chandeliers. The intricate work required a miniature spider crane with a lifting capacity of 0.995 tons. The crane’s compact size and precise handling ensured the preservation of the hotel’s historic architecture while completing the restoration. The ability to maneuver through narrow hallways and delicate interiors without causing damage was a significant advantage.

3. Masdar City, UAE: As part of an initiative to create an environmentally friendly urban zone, Masdar City utilizes spider cranes powered by liquefied gas. These cranes are used in construction and maintenance tasks within the city, aligning with the project’s sustainability goals. The use of eco-friendly equipment helps reduce the carbon footprint and ensures compliance with environmental standards.

Technological Advancements

Modern spider cranes can be equipped with electric drives, enhancing their appeal for indoor and environmentally sensitive applications. This capability has been particularly appreciated by museum workers and art restorers, who often deal with delicate and valuable objects. The ability to lift monuments and artworks weighing between 500-1500 kg to considerable heights without causing damage underscores the spider crane’s precision and reliability.

Electric drives offer several advantages, including reduced noise levels, zero emissions, and lower operating costs. These features make spider cranes ideal for use in hospitals, schools, and other sensitive environments where noise and pollution must be minimized. The ongoing development of battery technology also promises longer operating times and improved efficiency for electric-powered spider cranes.

Market Development and Awareness

Despite their numerous advantages, the adoption of spider cranes faces challenges due to insufficient awareness among potential users. Even large contractors may lack the necessary knowledge to utilize these machines effectively. Increasing awareness and understanding of spider cranes’ capabilities can significantly enhance their application in urban construction and other sectors.

Educational initiatives, demonstration projects, and industry partnerships can help bridge the knowledge gap and promote the benefits of spider cranes. As urbanization continues to grow, the demand for compact, efficient lifting solutions will likely increase, driving further innovation and market expansion.

Renting Spider Cranes

For those in Dubai seeking to leverage the capabilities of spider cranes, companies like Safest Lift offer a wide selection of lifting equipment to suit various needs. Renting a spider crane can provide an efficient and cost-effective solution for construction, restoration, and industrial projects, ensuring that even the most challenging tasks can be accomplished with ease.

Safest Lift provides expert advice and support, helping clients choose the right equipment for their specific requirements. Their fleet of spider cranes includes models with various lifting capacities, reach heights, and power options, ensuring that customers can find the perfect match for their project.

Conclusion

In conclusion, the spider crane stands out as a versatile, compact, and powerful tool, particularly suited for urban environments. Its development, driven by the needs of crowded Japanese cities, has paved the way for innovative solutions in construction and industrial applications worldwide. As awareness grows and technology advances, the spider crane’s role in modern industry is set to expand even further.

The spider crane’s ability to perform heavy lifting tasks in confined spaces, coupled with its eco-friendly options, makes it an invaluable asset in the ever-evolving landscape of urban construction and maintenance. By continuing to innovate and educate, the industry can unlock the full potential of these remarkable machines, ensuring safer, more efficient, and more sustainable operations in cities around the globe.

I am a powerful force in the workplace and use my positive attitude and tireless energy to help others work hard and achieve success.